Imagine a mobile platform that uses a robotic arm to 3D print entire buildings. Imagine a medical lab the size of a computer chip that can give doctors nearly instantaneous test results. Imagine a car that can drive you to your destination while you sit back and relax.

All of this might sound like science fiction, but these technologies are being researched and developed in labs across the country. As a student at MIT and now a grad student at Stanford University, Nathan Spielberg ’11 is working on cutting edge technologies with the potential to transform the way we live. In a very real sense, the labs that Nathan is working with are inventing the future.

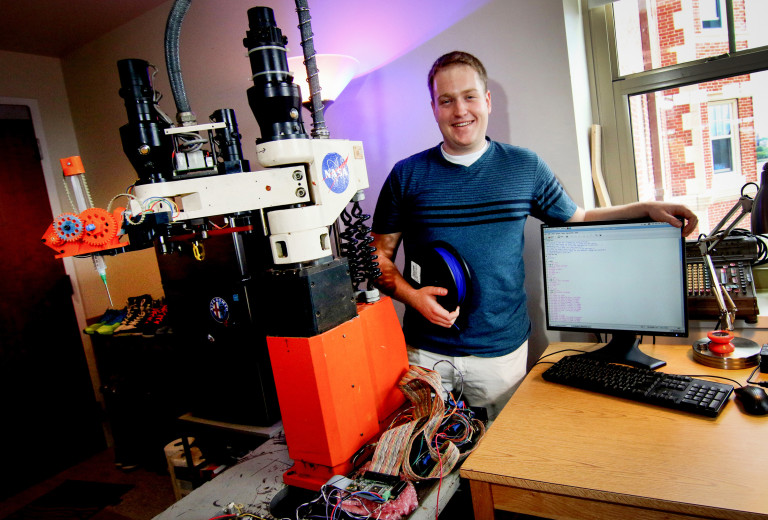

Nathan graduated from MIT last year with a degree in mechanical engineering. During his last two years, he worked primarily with 3D printers on projects that ranged from the very large to the very small. “I spent one year working with giant machines,” Nathan recalled, “and the next year working with machines where you needed a microscope to see the parts you built.”

His large scale project involved working with the Mediated Matter Research Group to help solve the engineering challenges of building a 3D printer able to work with precision on projects such as houses or other structures. The team that Nathan worked with developed a digital fabrication platform that consisted of a robotic arm attached to a boom arm truck. The device could build up entire structures layer by layer and has the potential to revolutionize how homes are built.

On the smaller scale, Nathan worked with the Mechanosynthesis Group on 3D printing a ‘lab on a chip,’ a miniaturized computer chip that can run a wide range of tests on a tiny sample of blood. The chip produces nearly instantaneous results, and Nathan believes there’s enormous potential in the technology for EMTs or military field medics.

Nathan believes that these extremes of scale are the future of 3D printing. “There are people trying to make medical devices that integrate with your body at really small scales, printing cells to make tissue, organs, or biologically compatible materials,” he explained. “There’s also printing at huge scales, like houses or cars.”

Nathan’s now a graduate student in mechanical engineering at Stanford, where he’s working with the Dynamic Design Lab on another futuristic project: autonomous vehicles, more popularly known as self-driving cars.

“I’m currently in a lab that’s working on testing autonomous cars at the limits of handling and stability,” he explained. “If you can design algorithms that make autonomous cars handle better in extreme situations, that could help with safety in existing cars in any situation where the car loses control, like sliding on the ice.”

Although he’s mostly working on programming the software that controls the cars, Nathan said that he also gets to do some of the mechanical work he loves. “We have one car that you can program for any experiment you want to do. It’s an electric car that you can program as a race car or to do user studies. I’ve been helping with a rear-end redesign of that car. We’re putting the drivetrain from a Tesla in it.”

Stanford tests its cars at Thunderhill Raceway a few hours north of campus, and Nathan said that he finds it satisfying to see his work in action. “For a lot of people in this field, the furthest they get is verifying that their simulation works on a computer. We have the hardware and the cars to test it out on the track or in user studies. Whatever you’re working on, you get to test it out at the end of the day.”

Nathan loves mechanical engineering because it lets him do the building and tinkering he enjoys so much. Last summer, Nathan got to share his enthusiasm with a group of middle school students during the summer Maker Corps classes hosted in the KCD Fab Lab.

“That was a really great experience,” he recalled. “The whole Maker movement is really awesome, and I wish there had been more of that when I was growing up. All that technology is making it so easy and convenient to make anything you can imagine. All the kids this past summer made robot arms in less than a week. They were all laser cut and able to move around and pick stuff up. It was amazing.”

Looking back, Nathan said he’s grateful for the math and science classes he took at KCD. “They did a really good job of getting me set up for my first year at MIT,” he said. “It was definitely harder than KCD, but I think there were people there who weren’t as well prepared for it as I was.”

Nathan’s not sure where he’s headed after grad school, but he loves the forward-looking research he’s involved with. “You get to be a part of the future of the field you’re in. I think that’s really neat.”

Photo courtesy of MIT

Carole, you should be proud!! What a bright and fabulous young man!